What are the product characteristics of load resistors?

What are the Product Characteristics of Load Resistors?

I. Introduction

A. Definition of Load Resistors

Load resistors are passive electrical components that are used to simulate a load in a circuit. They are designed to dissipate electrical energy in the form of heat, allowing engineers and technicians to test and analyze the performance of various electrical systems. By providing a known resistance, load resistors help in evaluating the behavior of power supplies, amplifiers, and other electronic devices under different load conditions.

B. Importance of Load Resistors in Electrical Circuits

In electrical engineering, load resistors play a crucial role in ensuring the stability and reliability of circuits. They are essential for testing and calibrating equipment, protecting sensitive components from overcurrent, and managing voltage levels. By mimicking real-world loads, these resistors enable engineers to assess how circuits will perform in actual applications, making them indispensable in both design and troubleshooting processes.

C. Purpose of the Article

This article aims to explore the product characteristics of load resistors, providing insights into their functionality, types, key specifications, performance characteristics, applications, and selection criteria. Understanding these aspects will help engineers and technicians make informed decisions when choosing load resistors for their projects.

II. Basic Principles of Load Resistors

A. Functionality of Load Resistors

1. Current Limiting

One of the primary functions of load resistors is to limit the current flowing through a circuit. By providing a specific resistance, they help prevent excessive current that could damage components or lead to circuit failure. This is particularly important in power electronics, where high currents can be common.

2. Voltage Division

Load resistors also play a role in voltage division, where they help distribute voltage across different components in a circuit. This is essential for ensuring that each component receives the appropriate voltage level for optimal performance.

B. Types of Load Resistors

1. Fixed Load Resistors

Fixed load resistors have a predetermined resistance value that does not change. They are commonly used in applications where a consistent load is required, such as in power supplies and testing equipment.

2. Variable Load Resistors

Variable load resistors, also known as rheostats or potentiometers, allow users to adjust the resistance value. This flexibility makes them ideal for applications that require fine-tuning of load conditions, such as in audio equipment and experimental setups.

3. Power Resistors

Power resistors are designed to handle high power levels and are built to dissipate heat effectively. They are often used in applications where significant energy is converted to heat, such as in braking systems for electric vehicles or in power amplifiers.

III. Key Product Characteristics of Load Resistors

A. Resistance Value

1. Ohmic Value and Tolerance

The resistance value of a load resistor is measured in ohms (Ω) and is a critical specification. It determines how much current will flow through the resistor when a voltage is applied. Tolerance indicates the allowable variation from the specified resistance value, which is important for precision applications.

2. Measurement Units (Ohms)

Load resistors are typically available in a wide range of resistance values, from fractions of an ohm to several megaohms. The choice of resistance value depends on the specific requirements of the application.

B. Power Rating

1. Definition and Importance

The power rating of a load resistor indicates the maximum amount of power it can safely dissipate without overheating. It is usually expressed in watts (W) and is a critical factor in ensuring the reliability and longevity of the resistor.

2. Power Dissipation and Heat Management

Effective heat management is essential for load resistors, especially in high-power applications. Resistors that exceed their power rating can fail, leading to circuit damage. Therefore, understanding the power dissipation characteristics and implementing proper cooling methods is vital.

C. Temperature Coefficient

1. Definition and Impact on Performance

The temperature coefficient of a resistor indicates how its resistance value changes with temperature. A low temperature coefficient is desirable for applications requiring stable performance across varying temperatures.

2. Types of Temperature Coefficients

Temperature coefficients are typically expressed in parts per million per degree Celsius (ppm/°C). Different materials used in resistors have varying temperature coefficients, affecting their suitability for specific applications.

D. Construction Material

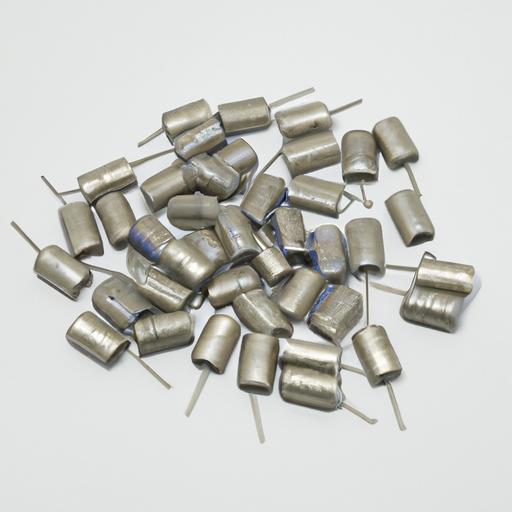

1. Common Materials Used (Carbon, Metal Film, Wirewound)

Load resistors can be made from various materials, including carbon, metal film, and wirewound. Each material has its advantages and disadvantages, influencing factors such as power handling, noise characteristics, and cost.

2. Impact of Material on Performance and Durability

The choice of construction material affects the resistor's performance, durability, and thermal stability. For instance, wirewound resistors are known for their high power ratings and stability, while carbon resistors are often more cost-effective but may have higher noise levels.

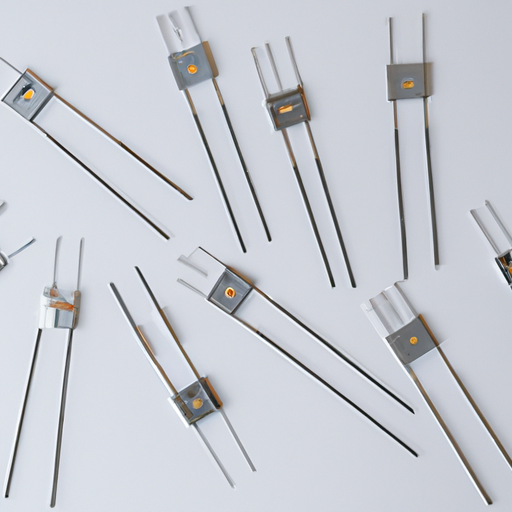

E. Size and Form Factor

1. Physical Dimensions

The size of a load resistor can vary significantly based on its power rating and construction type. Larger resistors typically have higher power ratings and better heat dissipation capabilities.

2. Mounting Options (Through-hole, Surface Mount)

Load resistors come in various mounting options, including through-hole and surface mount configurations. The choice of mounting type depends on the design of the circuit board and the available space.

F. Tolerance and Stability

1. Importance of Tolerance in Applications

Tolerance is a critical characteristic that affects the accuracy and reliability of load resistors. In precision applications, selecting resistors with low tolerance values is essential to ensure consistent performance.

2. Stability Over Time and Environmental Conditions

Load resistors should maintain their resistance values over time and under varying environmental conditions. Factors such as humidity, temperature fluctuations, and mechanical stress can impact stability, making it crucial to choose resistors designed for specific operating conditions.

IV. Performance Characteristics

A. Frequency Response

1. Impact of Frequency on Load Resistor Performance

The performance of load resistors can vary with frequency. At higher frequencies, parasitic capacitance and inductance can affect the resistor's behavior, leading to deviations from expected performance.

2. Applications Requiring Specific Frequency Response

Certain applications, such as RF circuits and audio equipment, require load resistors with specific frequency response characteristics to ensure optimal performance.

B. Noise Characteristics

1. Thermal Noise and Flicker Noise

Load resistors can generate noise, which can interfere with sensitive applications. Thermal noise, generated by the random motion of charge carriers, and flicker noise, which occurs at low frequencies, are two common types of noise associated with resistors.

2. Importance in Sensitive Applications

In applications such as audio processing and precision measurement, minimizing noise is critical. Selecting load resistors with low noise characteristics can significantly enhance overall system performance.

C. Reliability and Lifespan

1. Factors Affecting Reliability

The reliability of load resistors is influenced by factors such as operating temperature, power dissipation, and environmental conditions. Resistors that operate within their specified limits are more likely to have a longer lifespan.

2. Expected Lifespan in Various Conditions

Understanding the expected lifespan of load resistors under different conditions is essential for designing reliable circuits. Manufacturers often provide lifespan estimates based on typical operating conditions.

V. Applications of Load Resistors

A. Power Electronics

1. Use in Power Supplies and Converters

Load resistors are commonly used in power supplies and converters to simulate loads during testing and to ensure stable operation under varying conditions.

B. Testing and Measurement

1. Role in Circuit Testing and Calibration

In testing and calibration processes, load resistors provide a known reference point, allowing engineers to evaluate circuit performance and make necessary adjustments.

C. Audio Equipment

1. Use in Amplifiers and Signal Processing

Load resistors are integral to audio equipment, where they help manage signal levels and ensure optimal performance in amplifiers and signal processing circuits.

D. Automotive Applications

1. Load Resistors in Automotive Electronics

In automotive applications, load resistors are used in various electronic systems, including lighting and control circuits, to ensure proper operation and prevent overloading.

VI. Selecting the Right Load Resistor

A. Considerations for Selection

1. Application Requirements

When selecting a load resistor, it is essential to consider the specific requirements of the application, including resistance value, power rating, and environmental conditions.

2. Environmental Factors

Factors such as temperature, humidity, and mechanical stress should be taken into account to ensure the chosen resistor will perform reliably in the intended environment.

B. Common Mistakes to Avoid

1. Underestimating Power Ratings

One common mistake is underestimating the power rating required for a specific application. Choosing a resistor with an inadequate power rating can lead to failure and circuit damage.

2. Ignoring Temperature Coefficients

Another mistake is ignoring the temperature coefficient of the resistor. Selecting a resistor with a high temperature coefficient for a temperature-sensitive application can result in performance issues.

VII. Conclusion

A. Recap of Key Characteristics

Load resistors are essential components in electrical circuits, with key characteristics including resistance value, power rating, temperature coefficient, construction material, size, tolerance, and stability. Understanding these characteristics is crucial for selecting the right load resistor for specific applications.

B. Importance of Proper Selection for Performance

Proper selection of load resistors is vital for ensuring optimal performance, reliability, and longevity of electronic systems. Engineers and technicians must consider various factors, including application requirements and environmental conditions, to make informed choices.

C. Future Trends in Load Resistor Technology

As technology continues to evolve, advancements in materials and manufacturing processes are likely to lead to improved load resistor designs. Innovations may focus on enhancing power handling, reducing noise, and increasing reliability, further expanding the applications of load resistors in modern electronics.

VIII. References

A. Suggested Reading and Resources

1. "Electronic Components: A Complete Reference for Project Builders" by Delton T. Horn

2. "The Art of Electronics" by Paul Horowitz and Winfield Hill

B. Industry Standards and Guidelines

1. IEC 60115 - Fixed Resistors for Use in Electronic Equipment

2. EIA-198 - Standard for Resistor Networks and Arrays

This comprehensive overview of load resistors highlights their critical characteristics and applications, providing valuable insights for engineers and technicians involved in electronic design and testing. Understanding these aspects will enable better decision-making and enhance the performance of electrical systems.