What are the product characteristics of the resistor factory?

Product Characteristics of a Resistor Factory

I. Introduction

A. Definition of Resistors

Resistors are passive electronic components that limit the flow of electric current in a circuit. They are essential for controlling voltage and current levels, ensuring that electronic devices operate safely and effectively. By providing a specific resistance, they help manage the electrical energy within circuits, making them fundamental to virtually all electronic applications.

B. Importance of Resistors in Electronic Circuits

In electronic circuits, resistors play a critical role in protecting sensitive components, dividing voltages, and setting bias points for transistors. They are used in a wide range of applications, from simple household electronics to complex industrial machinery. Without resistors, circuits would be prone to overloads, leading to component failure and potential hazards.

C. Overview of Resistor Manufacturing

The manufacturing of resistors involves a series of precise processes that ensure the final product meets specific electrical and physical characteristics. This blog post will explore the various types of resistors, their key product characteristics, manufacturing processes, quality assurance measures, and current market trends.

II. Types of Resistors

A. Fixed Resistors

Fixed resistors have a predetermined resistance value that cannot be changed. They are the most common type of resistors and include:

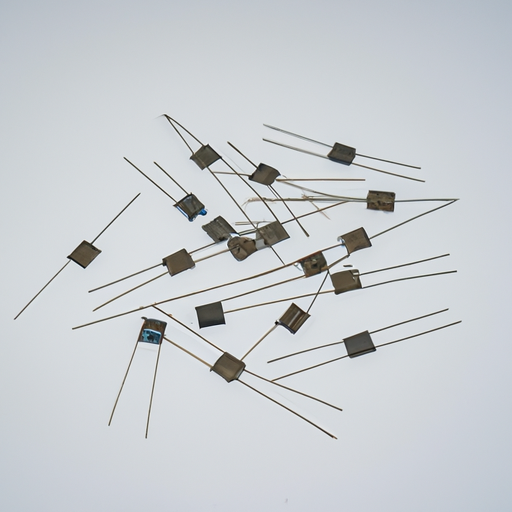

1. **Carbon Composition Resistors**: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption and ability to withstand high temperatures. However, they have a higher tolerance and are less stable than other types.

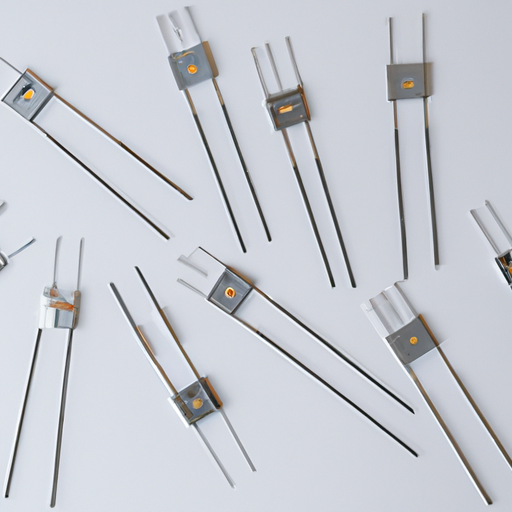

2. **Metal Film Resistors**: These resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer better stability and lower noise levels compared to carbon composition resistors, making them suitable for precision applications.

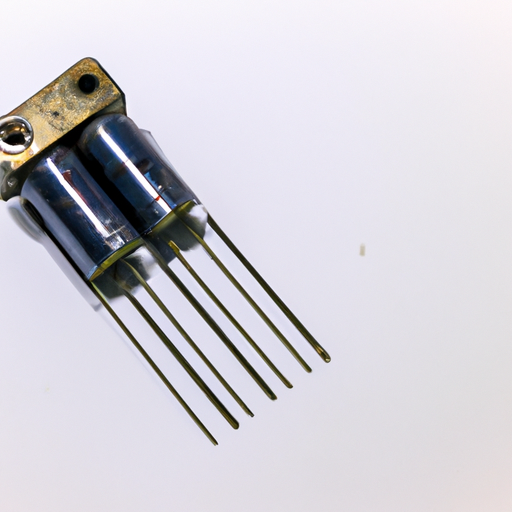

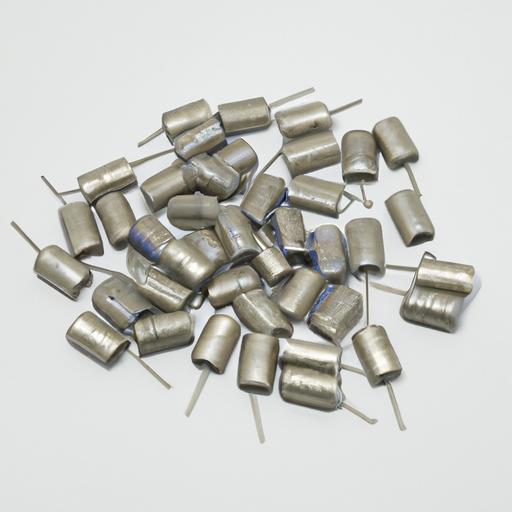

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in high-frequency applications.

B. Variable Resistors

Variable resistors allow for adjustable resistance values, making them versatile components in electronic circuits. They include:

1. **Potentiometers**: Used for adjusting voltage levels, potentiometers are commonly found in volume controls and other user-adjustable settings.

2. **Rheostats**: Similar to potentiometers but designed to handle higher currents, rheostats are used in applications where variable resistance is needed, such as in light dimmers.

C. Specialty Resistors

Specialty resistors are designed for specific applications and include:

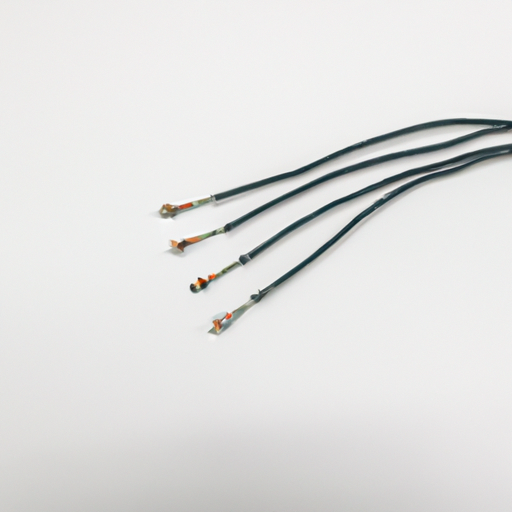

1. **Thermistors**: Temperature-sensitive resistors that change resistance with temperature variations, thermistors are widely used in temperature sensing and control applications.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these components change resistance based on light exposure, making them ideal for light-sensing applications.

III. Key Product Characteristics

A. Resistance Value

The resistance value of a resistor is measured in ohms (Ω) and is a fundamental characteristic that determines how much current will flow through it.

1. **Measurement Units (Ohms)**: The ohm is the standard unit of resistance, and resistors are available in a wide range of values to suit different applications.

2. **Tolerance Levels**: Tolerance indicates how much the actual resistance can vary from the stated value. Common tolerance levels include ±1%, ±5%, and ±10%, with lower tolerance values indicating higher precision.

B. Power Rating

The power rating of a resistor indicates the maximum amount of power it can dissipate without overheating.

1. **Definition and Importance**: Power ratings are crucial for ensuring that resistors can handle the electrical load without failure.

2. **Heat Dissipation and Thermal Management**: Effective thermal management is essential in resistor design, as excessive heat can lead to component failure. Manufacturers often use materials and designs that enhance heat dissipation.

C. Temperature Coefficient

The temperature coefficient measures how much a resistor's resistance changes with temperature.

1. **Definition and Impact on Performance**: A low temperature coefficient indicates that the resistor will maintain its resistance value over a wide temperature range, which is critical for precision applications.

2. **Types of Temperature Coefficients**: Resistors can have positive or negative temperature coefficients, affecting their performance in varying thermal conditions.

D. Voltage Rating

The voltage rating indicates the maximum voltage that can be applied across a resistor without causing breakdown.

1. **Definition and Importance**: Exceeding the voltage rating can lead to resistor failure, making it a vital characteristic for circuit design.

2. **Breakdown Voltage Considerations**: Manufacturers must consider the breakdown voltage when designing resistors, especially for high-voltage applications.

E. Physical Dimensions

The physical size and form factor of a resistor can impact its application and mounting options.

1. **Size and Form Factor**: Resistors come in various sizes, from tiny surface-mount devices (SMD) to larger through-hole components, allowing for flexibility in design.

2. **Mounting Options (Through-hole vs. Surface Mount)**: Through-hole resistors are typically used in larger, more robust applications, while surface-mount resistors are favored in compact, high-density circuit designs.

IV. Manufacturing Processes

A. Material Selection

The choice of materials is critical in resistor manufacturing.

1. **Conductive Materials**: Common conductive materials include carbon, metal films, and metal wire, each chosen based on the desired resistor type and application.

2. **Insulating Materials**: Insulating materials are used to prevent electrical leakage and ensure safety, with ceramics and plastics being popular choices.

B. Production Techniques

Manufacturing processes can vary significantly based on the type of resistor being produced.

1. **Automated vs. Manual Processes**: Many resistor factories utilize automated processes for efficiency and consistency, while some specialized resistors may still be produced manually.

2. **Quality Control Measures**: Rigorous quality control is essential to ensure that resistors meet specified characteristics and performance standards.

C. Testing and Validation

Testing is a crucial step in the manufacturing process.

1. **Electrical Testing**: Resistors undergo electrical testing to verify their resistance values, power ratings, and other electrical characteristics.

2. **Environmental Testing**: Environmental testing assesses how resistors perform under various conditions, including temperature fluctuations and humidity.

V. Quality Assurance and Standards

A. Industry Standards (e.g., ISO, RoHS)

Resistor manufacturers must adhere to industry standards to ensure product quality and safety. Compliance with standards such as ISO (International Organization for Standardization) and RoHS (Restriction of Hazardous Substances) is essential for market acceptance.

B. Certification Processes

Certification processes help validate that resistors meet specific performance and safety criteria, providing assurance to manufacturers and consumers alike.

C. Importance of Quality Control in Resistor Manufacturing

Quality control is vital in resistor manufacturing to prevent defects and ensure reliability. Consistent quality helps maintain customer trust and satisfaction.

VI. Customization and Special Orders

A. Tailored Resistance Values

Many resistor factories offer customization options, allowing customers to specify unique resistance values for specialized applications.

B. Unique Form Factors

Customization can also extend to form factors, enabling manufacturers to produce resistors that fit specific design requirements.

C. Specialized Applications (e.g., automotive, aerospace)

Certain industries, such as automotive and aerospace, require resistors that meet stringent performance and safety standards, leading to specialized manufacturing processes.

VII. Market Trends and Innovations

A. Advances in Materials Science

Recent advancements in materials science have led to the development of new resistor types with improved performance characteristics, such as higher power ratings and lower temperature coefficients.

B. Miniaturization and Integration

The trend toward miniaturization in electronics has driven the demand for smaller, more efficient resistors that can be integrated into compact designs.

C. Sustainability and Eco-Friendly Practices

As environmental concerns grow, many resistor manufacturers are adopting sustainable practices, such as using eco-friendly materials and reducing waste in the production process.

VIII. Conclusion

A. Summary of Key Product Characteristics

Resistors are vital components in electronic circuits, with various types and key characteristics that determine their performance. Understanding these characteristics is essential for selecting the right resistor for specific applications.

B. The Role of Resistor Factories in the Electronics Industry

Resistor factories play a crucial role in the electronics industry, providing the components necessary for the safe and efficient operation of electronic devices.

C. Future Outlook for Resistor Manufacturing

As technology continues to evolve, the resistor manufacturing industry will likely see further innovations in materials, design, and production processes, ensuring that resistors remain integral to the future of electronics.

IX. References

A. Academic Journals

- Various academic journals on electronics and materials science.

B. Industry Reports

- Reports from industry analysts on trends in resistor manufacturing.

C. Manufacturer Specifications and Guidelines

- Specifications and guidelines from leading resistor manufacturers.

This comprehensive overview of the product characteristics of a resistor factory highlights the importance of resistors in electronic circuits and the intricate processes involved in their manufacturing. Understanding these elements is crucial for anyone involved in electronics design and production.