What is the mainstream high-voltage resistor production process?

Mainstream Production Process of High Voltage Resistors

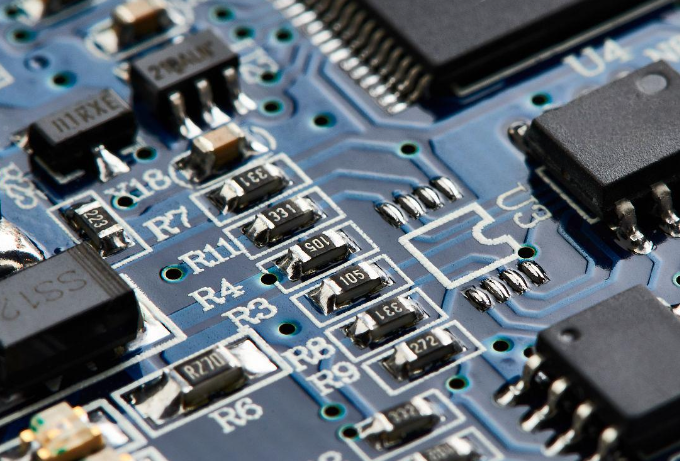

1. Material Preparation The main material of high voltage resistors is ceramic, usually aluminum oxide or zirconium oxide. These materials have excellent insulation properties and high temperature stability, making them ideal for manufacturing high voltage resistors. In the production process, it is necessary to prepare these ceramic materials first, and mix and grind them in certain proportions to ensure the uniformity and stability of the materials.

2. Forming Forming is the first step in the production of high voltage resistors, usually using injection molding technology. In this process, the mixed ceramic powder is placed into the injection molding machine, and through high-pressure injection molding, it is pressed into the desired shape of resistor blanks. The formed blanks need to undergo a certain drying and sintering process to ensure the stability of their structure and the uniformity of their density.

3. Sintering Sintering is a key step in the production of high voltage resistors. High temperature sintering can crystallize the ceramic materials and form a dense structure. During the sintering process, it is necessary to control the sintering temperature and time to ensure the performance and stability of the resistors. The sintered resistor blanks need to undergo surface treatment, usually by grinding or coating a protective layer to improve their appearance and durability.

4. Metallization Metallization is another important step in the production of high voltage resistors. By coating a layer of metal film on the surface of the resistor, its conductivity and stability can be improved. Vacuum deposition or spraying technology is usually used to evenly cover the resistor surface with a metal film. The metallized resistors need to be baked and tested to ensure the adhesion and conductivity of the metal film.

5. Testing and Packaging The final step is to test and package the high voltage resistors. During testing, the resistance value, voltage resistance performance, and temperature characteristics of the resistors need to be checked to ensure they meet the design requirements. Once the testing is qualified, the resistors are packaged, usually in vacuum packaging or plastic packaging, to protect them from external environmental influences.

Conclusion The production process of high voltage resistors involves multiple steps, including material preparation, forming, sintering, metallization, testing, and packaging. By carefully designing and strictly controlling the process parameters of each step, high-quality and reliable high voltage resistor products can be produced. With the continuous development of electronic devices and increasing demand, the production process of high voltage resistors is constantly innovating and improving to meet market demands and customer requirements. It is hoped that through this introduction, readers have gained a deeper understanding of the production process of high voltage resistors.

Mainstream Production Process of High Voltage Resistors

1. Material Preparation The main material of high voltage resistors is ceramic, usually aluminum oxide or zirconium oxide. These materials have excellent insulation properties and high temperature stability, making them ideal for manufacturing high voltage resistors. In the production process, it is necessary to prepare these ceramic materials first, and mix and grind them in certain proportions to ensure the uniformity and stability of the materials.

2. Forming Forming is the first step in the production of high voltage resistors, usually using injection molding technology. In this process, the mixed ceramic powder is placed into the injection molding machine, and through high-pressure injection molding, it is pressed into the desired shape of resistor blanks. The formed blanks need to undergo a certain drying and sintering process to ensure the stability of their structure and the uniformity of their density.

3. Sintering Sintering is a key step in the production of high voltage resistors. High temperature sintering can crystallize the ceramic materials and form a dense structure. During the sintering process, it is necessary to control the sintering temperature and time to ensure the performance and stability of the resistors. The sintered resistor blanks need to undergo surface treatment, usually by grinding or coating a protective layer to improve their appearance and durability.

4. Metallization Metallization is another important step in the production of high voltage resistors. By coating a layer of metal film on the surface of the resistor, its conductivity and stability can be improved. Vacuum deposition or spraying technology is usually used to evenly cover the resistor surface with a metal film. The metallized resistors need to be baked and tested to ensure the adhesion and conductivity of the metal film.

5. Testing and Packaging The final step is to test and package the high voltage resistors. During testing, the resistance value, voltage resistance performance, and temperature characteristics of the resistors need to be checked to ensure they meet the design requirements. Once the testing is qualified, the resistors are packaged, usually in vacuum packaging or plastic packaging, to protect them from external environmental influences.

Conclusion The production process of high voltage resistors involves multiple steps, including material preparation, forming, sintering, metallization, testing, and packaging. By carefully designing and strictly controlling the process parameters of each step, high-quality and reliable high voltage resistor products can be produced. With the continuous development of electronic devices and increasing demand, the production process of high voltage resistors is constantly innovating and improving to meet market demands and customer requirements. It is hoped that through this introduction, readers have gained a deeper understanding of the production process of high voltage resistors.