What is the production process of mainstream resistor manufacturers?

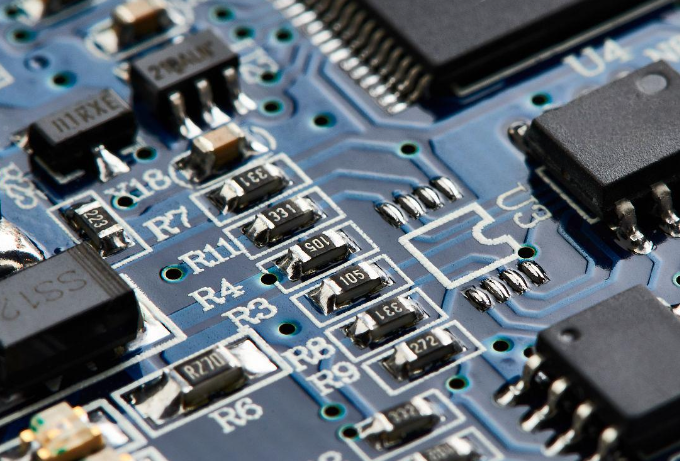

The production process of mainstream resistor manufacturers is a complex and precise process that requires strict quality control and high technical requirements. In modern industry, resistors are common electronic components used to limit current, regulate voltage, and divide voltage in circuits. Therefore, the production process of resistors is crucial for the performance and stability of electronic products.

Secondly, mainstream resistor manufacturers need to design appropriate production processes. The production process includes material preparation, printing, sintering, cutting, testing, and other processes. In the material preparation stage, the raw materials need to be screened, mixed, and prepared into a slurry. In the printing stage, the slurry needs to be printed on the substrate and solidified by baking. In the sintering stage, the solidified resistors need to be sintered at high temperatures to have stable resistance values and temperature characteristics. In the cutting stage, the sintered resistors need to be cut into appropriate sizes. Finally, in the testing stage, the resistors need to be tested for resistance values, temperature coefficients, power capacities, and other performance indicators to ensure that the products meet the requirements.

Furthermore, mainstream resistor manufacturers need to introduce advanced production equipment and technology. Modern resistor production lines are usually equipped with automation equipment such as printers, sintering furnaces, cutters, testers, etc., to achieve efficient and precise production. At the same time, manufacturers need to continuously improve the production process, improve product quality, and production efficiency.

In conclusion, the production process of mainstream resistor manufacturers is a comprehensive process that requires comprehensive consideration in material selection, process design, equipment introduction, etc. Only by continuously improving technical levels, optimizing production processes, can high-quality, stable performance resistor products be produced to meet market demand.

The production process of mainstream resistor manufacturers is a complex and precise process that requires strict quality control and high technical requirements. In modern industry, resistors are common electronic components used to limit current, regulate voltage, and divide voltage in circuits. Therefore, the production process of resistors is crucial for the performance and stability of electronic products.

Secondly, mainstream resistor manufacturers need to design appropriate production processes. The production process includes material preparation, printing, sintering, cutting, testing, and other processes. In the material preparation stage, the raw materials need to be screened, mixed, and prepared into a slurry. In the printing stage, the slurry needs to be printed on the substrate and solidified by baking. In the sintering stage, the solidified resistors need to be sintered at high temperatures to have stable resistance values and temperature characteristics. In the cutting stage, the sintered resistors need to be cut into appropriate sizes. Finally, in the testing stage, the resistors need to be tested for resistance values, temperature coefficients, power capacities, and other performance indicators to ensure that the products meet the requirements.

Furthermore, mainstream resistor manufacturers need to introduce advanced production equipment and technology. Modern resistor production lines are usually equipped with automation equipment such as printers, sintering furnaces, cutters, testers, etc., to achieve efficient and precise production. At the same time, manufacturers need to continuously improve the production process, improve product quality, and production efficiency.

In conclusion, the production process of mainstream resistor manufacturers is a comprehensive process that requires comprehensive consideration in material selection, process design, equipment introduction, etc. Only by continuously improving technical levels, optimizing production processes, can high-quality, stable performance resistor products be produced to meet market demand.